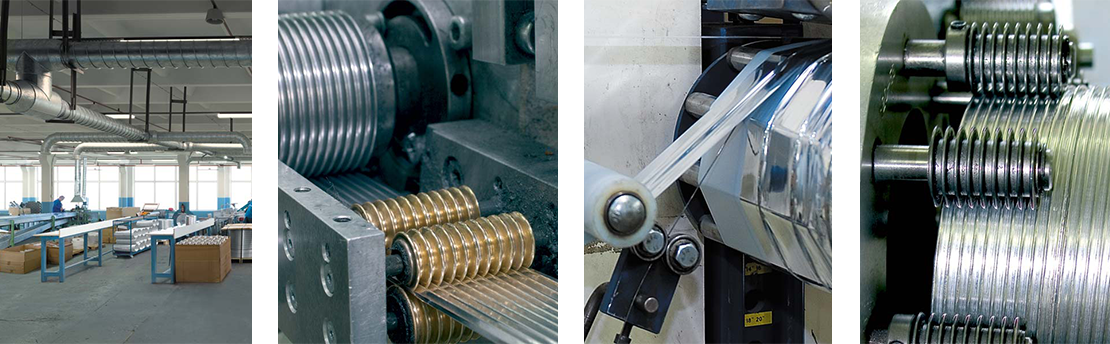

Workshop for flexible air ducts manufacturing produces a wide range of products under its own trademarks “Polivent”, “Aluvent”, “Isovent” and “Thermovent”. The air ducts are manufactured using high-technology equipment of world’s leading manufacturers and are made from quality European materials (aluminium foil, metallized polyester film, PVC-film, polyurethane, aluminium, galvanized and stainless steel). Thanks to this, all manufactured products are environmentally safe and comply with the highest international quality standards, as well as meet the requirements for leak integrity, rigidness, non-flammability, safety and other parameters.